Explore Now

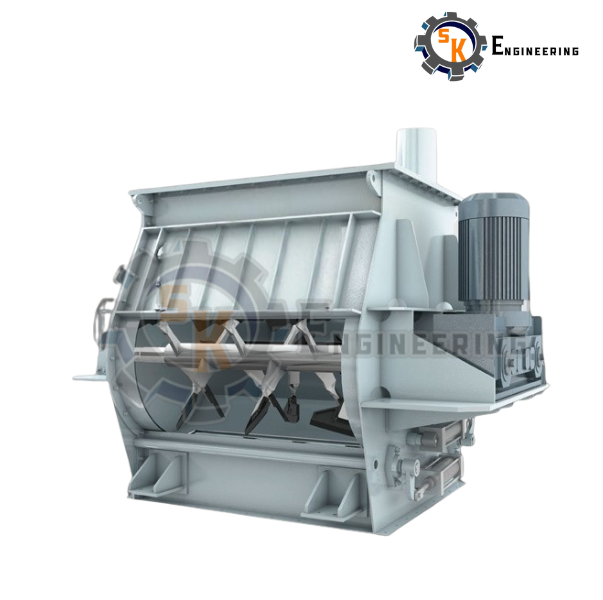

SK Twin-Shaft Paddle Mixer

Our SK Twin-Shaft Paddle Mixer is engineered for fast, uniform, and contamination-free mixing of powders, granules, and moist materials. Designed with a robust twin-shaft counter-rotating system, it delivers rapid blending with exceptional accuracy, making it ideal for a wide range of industries including chemicals, food processing, construction materials, pharmaceuticals, and agriculture.

The mixer’s specially designed paddles generate a fluidized mixing zone, ensuring every particle is lifted, suspended, and blended evenly within seconds. This results in maximum homogeneity, minimal product degradation, and ultra-short mixing cycles.

Built with a heavy-duty stainless steel body, large inspection doors, and easy-clean access points, this mixer offers superior hygiene, complete discharge, and low maintenance. Its high-efficiency drive system reduces power consumption while maintaining maximum output.

Whether you’re handling powders, granules, or wet mixtures, this Twin-Shaft Paddle Mixer ensures consistent quality, faster production, and long-term reliability, making it the perfect solution for modern manufacturing.

Technical Specifications – Twin-Shaft Paddle Mixer

1. General

2. Construction

3. Performance

4. Feeding & Discharge

5. Motor & Power

6. Optional Features

7. Typical Applications